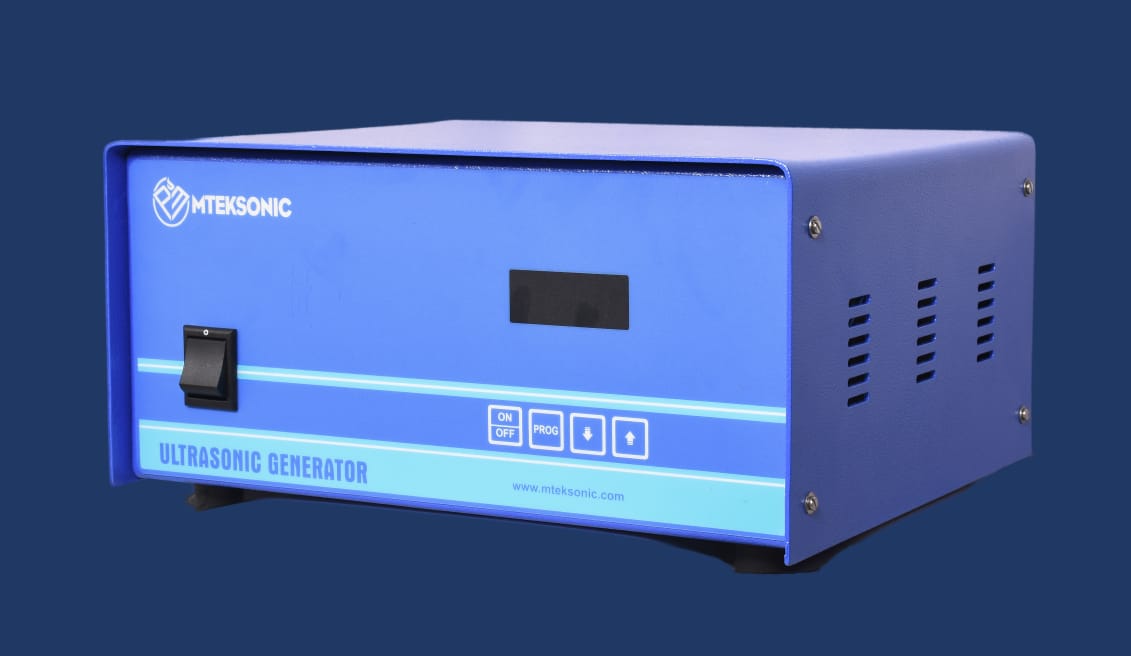

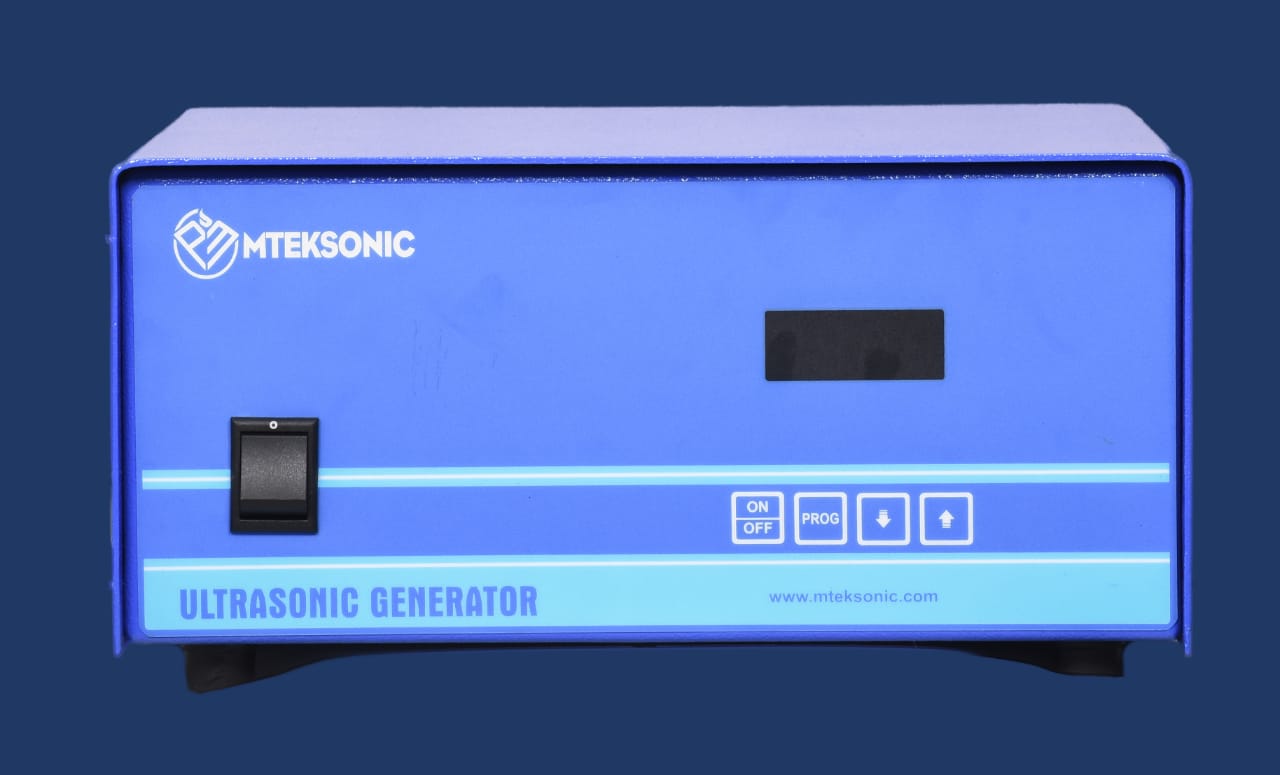

Ultrasonic Tube Resonator

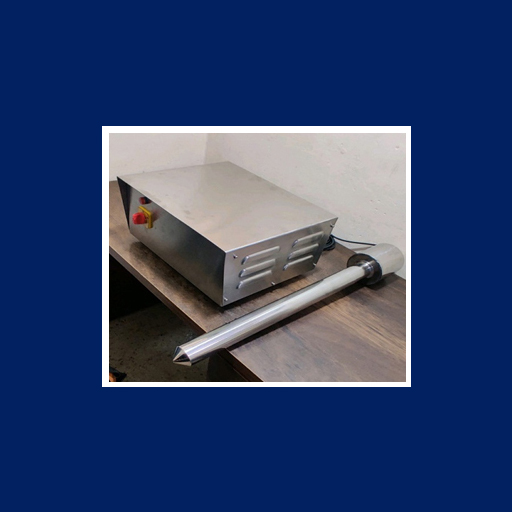

We offer the right Resonator model and related generator for any cleaning requirement. Ranges of frequencies and performance classes are available, as are specific dimensions. Furthermore, rod transducers can be equipped with one or two mounting points – Resonator can be used to outfit or retro-fit any system. can be easily refitted to existing chambers. Your cleaning units run smoothly and require no time-consuming maintenance work.

Category: Ultrasonic Cleaning Technology

We offer the right Resonator model and related generator for any cleaning requirement. Ranges of frequencies and performance classes are available, as are specific dimensions. Furthermore, rod transducers can be equipped with one or two mounting points – Resonator can be used to outfit or retro-fit any system. can be easily refitted to existing chambers. Your cleaning units run smoothly and require no time-consuming maintenance work.

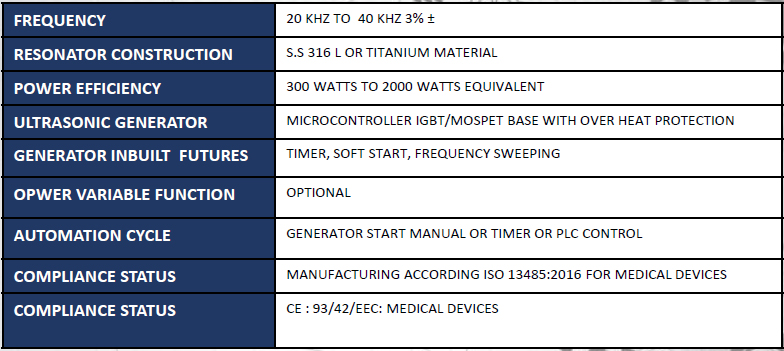

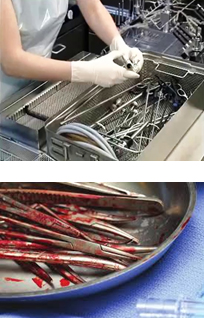

Cleanliness requirements for parts and surfaces in all industries and applications keep increasing. To allow seamless processing and to minimize failure rate the cleanliness level of individual components becomes a critical quality factor. And this is exactly where ultrasonic technology, suitable for coarse, fine, and ultra-fine cleaning from 20 to 40 kHz, comes into play. Users not only save of time and additives, but the high cleaning power also reduces energy consumption. These factors make ultrasound an especially sustainable technology.

ABOUT OUR TUBE TRANSDUCERS

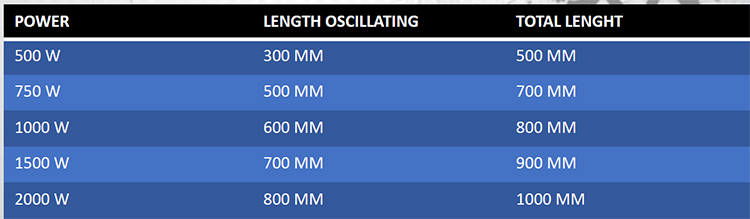

- • Output power up-to 500 watts to 1500 watts with 95% efficiency.

- • Operation at temperatures up to 95°C

- • 360-degree effect: sound field with outstanding efficiency

- • Space-saving design

- • Can be Installed in closed systems or open cleaning tanks

- • Frequency 25 KHZ / 30 KHZ / 40 KHZ

- • Long life use, to save machine fabrication cost.

Transducer bonded in tank bottom, this technology may damage tank bottom after few years.

Tube Resonator technology is mount at any direction, no surface contact hence no damages.