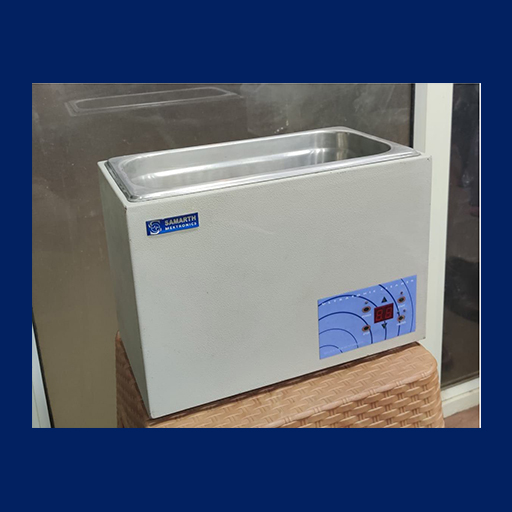

Ultrasonic Cleaner

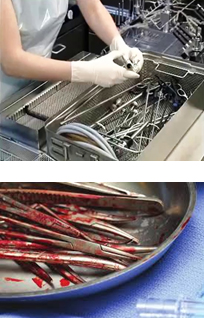

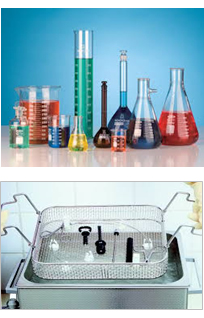

Ultrasonic Cleaner removes micro dust, clot, and blood stains, in instruments/scopes in 3 to 5 minutes. Maintains the sharp edges of the instruments and totally eliminates the breakage of fragile glassware apparatus like test tubes, pipettes, etc.

Category: Ultrasonic Cleaning Machine

Tag: Ultrasonic Cleaner

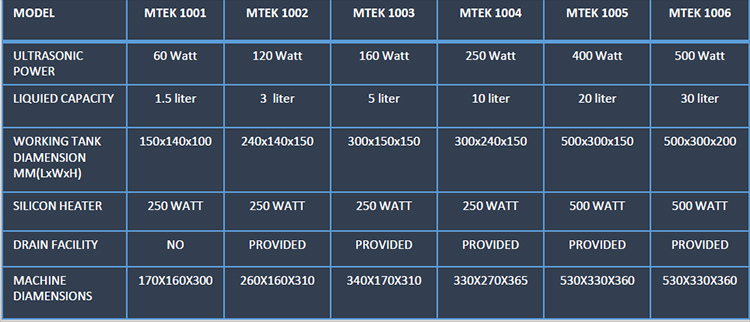

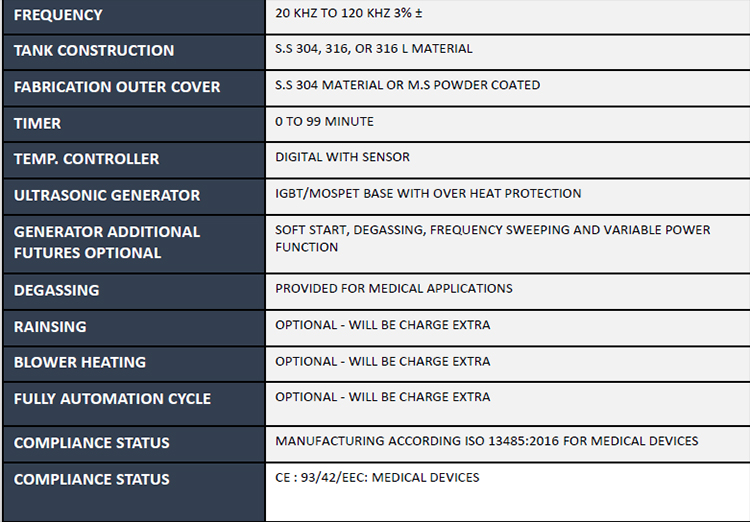

MTEKSONIC is dedicated to the design and manufacturing of Medical, Industrial & Pharmaceutical Ultrasonic cleaning equipment. We are committed to offer to our clients the best services and the latest science and technology advances in Medical & Industrial ultrasonic cleaning machines.

Ultrasonic Cleaning at higher frequencies ( 20 KHZ to 120 KHZ ) creates an abundance minute vacuum bubbles with which allow for cleaning occur. These bubbles implode on and inside surgical device surface in a process defined as cavitation. This Micromechanical scrubbing action is able to reach small crevices, irregular surface, and internal passages to ensure proper and consistent cleaning.

Ultrasonic Cleaner removes micro dust, clot, and blood stains, in instruments/scopes in 3 to 5 minutes. Maintains the sharp edges of the instruments and totally eliminates the breakage of fragile glassware apparatus like test tubes, pipettes, etc.